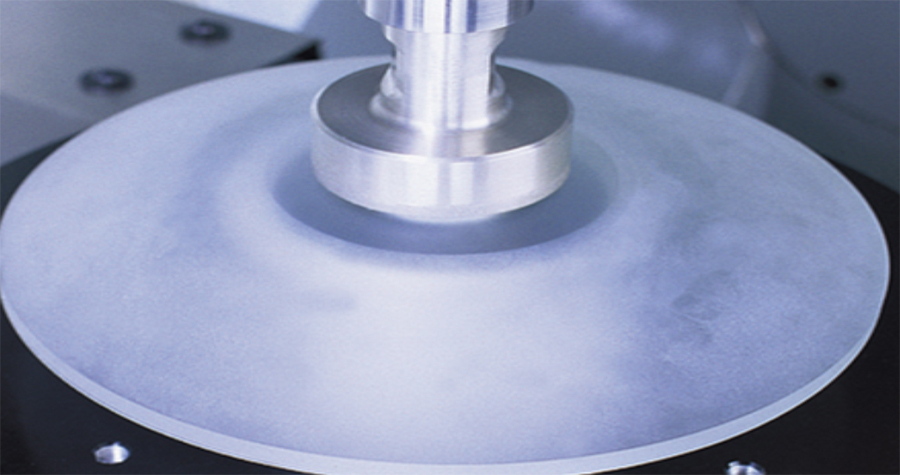

We have a wide variety of custom abrasive diamond tools, like hollow drills including a countersink which can drill a hole while simultaneously adding a chamfer. We are focused on developing the perfect solutions, i.e. you always get an optimized tool for your particular application from us.

We can develop a variety of binders suitable for the material to be processed. These solutions are based on Schott’s 30 years experience in the field of diamond tool manufacturing. The development of a special tools is according to the specifications of our customers. To do so, we can either cooperate with you or manufacture a tool according to our experience.

With our products, you can enjoy an unlimited range of special custom tools which are ideally suited for your applications:

- all diamond abrasive grain sizes are possible

- all bonds (from hard to soft) for different materials

- bore depths up to 300mm ( technically dependent on the Ø of the drill)

- all diamond abrasive drill diameters and intermediate diameters available

- variable wall thicknesses and crown heights

- Diamond abrasive tools can be manufactured with or without slots for optimal coolant flow

- tool holder connections according to your specifications

- all standard profiles for grinding wheels but also special profiles suitable for the processing of display glass

- for grinding wheels, many different widths of the coatings and heights are available

- Choice between conventional tools and ultrasonic tools

- Various geometries are available

- galvanic tools, either coated or hollow